30 Apr The Importance of PPE for Spray Foam Installers

What is Personal Protective Equipment?

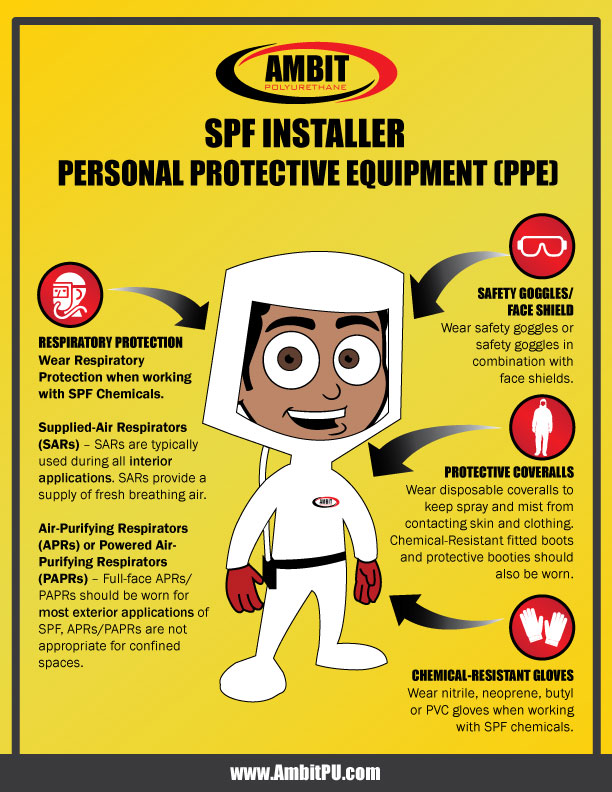

Personal Protective Equipment, or PPE, is specialized clothing or equipment worn by employees for protection against health and safety hazards. PPE is designed to protect many parts of the body, including eyes, head, hands, feet and the respiratory tract.

Why is it Important to Wear PPE while Handling or Installing Spray Foam Insulation?

PPE is critical for workers in order to avoid inhalation of the SPF chemicals and to avoid contact with the skin and eyes. In order to avoid potential exposure to SPF chemicals, the appropriate PPE should be worn, including at minimum, chemical-resistant gloves, protective clothing, eye and face protection and respiratory protection. The specific types of PPE may vary depending on the conditions at the jobsite and the potential exposure to the SPF chemicals.

What PPE are Spray Foam Insulation Installers Required to Use When Installing Spray Foam Insulation?

Face and Eye Protection

- Safety Goggles/Face Shields – Persons handling open containers of SPF chemicals should wear safety goggles or safety goggles in combination with face shields.

- Full Face Respirator or Hood – During the installation of SPF, eye protection may be provided by wearing a full-face or hood respirator.

Skin and Body Protection

- Protective Clothing – Installers and Helpers typically should wear disposable coveralls to keep spray and mist from contacting skin and clothing. (No skin should be exposed.) When not wearing a hood respirator, select a coverall with an attached hood or head cover. For tasks where there is a potential for splash, boots coated with an impermeable coating such as PVC and MDI-Resistant fitted boots/booties should be worn.

- Chemical-Resistant Gloves – Nitrile, neoprene, butyl or PVC gloves should be worn when working with SPF chemicals. Gloves should fit perfectly and should not be too large or too small.

Respiratory Protection

- Air-Purifying Respirators (APRs) – Full-face APRs should be worn for exterior applications of SPF, however APR’s are not appropriate in confined spaces and should not be warn in areas with less than 19.5% oxygen or where air concentrations of MDI are less than 0.250 parts per million (equal to 50 times the 8-hour occupational exposure limit).

- Powered Air-Purifying Respirators (PAPRs) – PAPRs are APRs equipped with a battery powered blower unit which supplies filtered breathing air to the user’s facepiece. PAPRs can be used in place of APRs and are typically used in hot outdoor climates as it provides an air-conditioned-like effect, making the air cooler and more comfortable for the user.

- Supplied-Air Respirators (SARs) – SARs are typically used during all interior applications. SARs provide a supply of fresh breathing air from an outside source such as a compressor, bottled compressed air, or a low-pressure pump attached to an air-line hose. SARs are referred to as Type C systems or air-line respirators. SARs provide the greatest protection for the user.

To find out more about the importance of PPE for SPF Installers and Workers, visit https://www.spraypolyurethane.org/personal-protective-equipment-ppe/.

To learn more about AMBIT’s line of spray foam insulation products or how to become an AMBIT Approved Installer, please contact us.

Sorry, the comment form is closed at this time.